- -30%

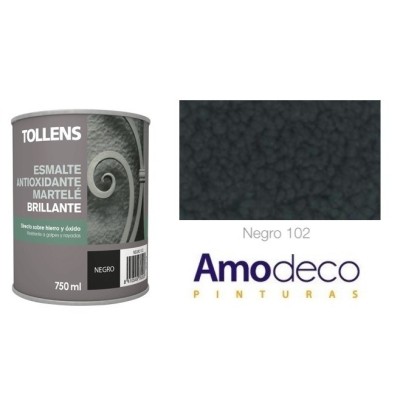

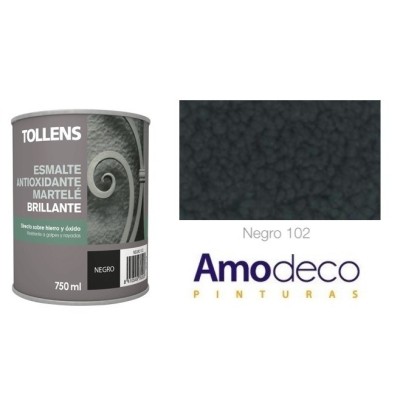

Rustproof enamel-paint. Direct application on steel, no primerresistance and a high gloss hammered finish. High adhesion. Hardwearing. Resistant to impact and scratches.

Description

Antioxidant enamel with shiny metallic finish applied directly on iron and oxide. Of very decorative texture that, at the same time, it conceals the imperfections of the surface.

Main Properties

Certificates:

Applications:

For doors, street lamps, bars, railings, furniture and any element of iron in exterior or interior.

PREPARING THE SUPPORT

Surfaces must always be clean, dry and free of grease, dust and loose rust.

Yield: 8-12 m² / Lt (approximate and according to support).

Drying (by color, thickness applied and room temperature)

Number of layers: In metal previously painted and in good condition, apply 2 hands. If necessary and to achieve the proper effect, apply 3 hands. If it is discovered or oxidized and in areas of welding, apply 3 hands. On metal subjected to extreme conditions, we recommend to apply the Antioxidant Primer to the solvent beforehand. Cover corners and edges well.

Application tools: Airbrush, roller or spray gun / air-less.

Dilution:

Cleaning: Solvent

Chat with us on WhatsApp